Among the various segments of the global container fleet, refrigerated containers (reefers) are the fastest growing. This growth is in no small part due to the increasing need for transport of temperature-controlled goods and products, according to PR Newswire.

Additionally, as transparency in the global supply chain becomes a priority for many international and domestic shipping companies, businesses are making the most of smart technologies such as digital monitoring in reefers to provide the level of transparency their clients and consumers demand.

Real-time monitoring provides greater transparency in international shipping of refrigerated goods.

In an on-going quest to provide improved transparency at all stages in the shipping process Maersk Container Industry has introduced real-time energy monitoring in its ‘Star Cool’ reefer line. An industry first, this technology gives customers the ability to monitor the energy consumption of their reefers at any point in the journey.

“Taking our 270,000 reefer containers online has provided significant operational cost savings and will give our customers unprecedented visibility into their cargo during transport, enabling better planning across their supply chains,” said Catja Hjorth Rasmussen, Head of Equipment Excellence at Maersk Line in a report by Hellenic Shipping News.

Reefer containers are ideal for the safe transportation of frozen foods such as fruits and vegetables. Yet what about the materials these goods are packed on? As more and more reefers make their way onto the global platform, what pallet solutions are there to support them?

Reefer containers are ideal for the safe transportation of frozen foods such as fruits and vegetables.

Choosing the right pallet material for reefers

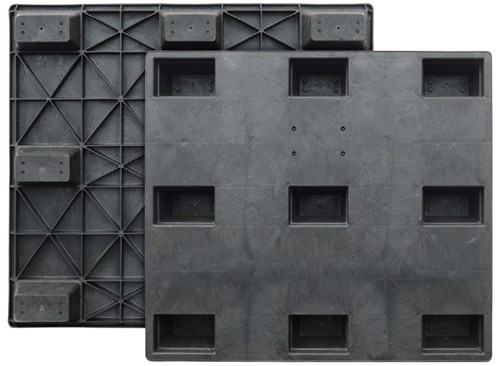

Providing transportation materials that can withstand sub-zero temperatures for extended periods of time is essential for maintaining the integrity of the transported goods and ensuring they arrive at the destination in the same conditions as they left. Eco Pallets Export Pallets fit the bill for the export of refrigerated and frozen goods with several handy features:

- Can easily handle sub-zero temperatures over long periods without degrading or weakening.

- Plastic composition makes it the hygienic option, able to be hot washed, steamed or chemically cleaned.

- A 1090 x 1090 mm footprint makes them an ideal internal fit for reefers, saving on space.

As shipping and transport becomes increasingly transparent and accountable world-wide, supporting this trend are Eco Pallets. Our robust, customisable plastic pallets are the ideal, cost-effective solution for the transportation of foods, beverages and other goods.

To find out more about our pallet solutions, reach out to a member of our team today.

Comments are closed.